A Major Step Toward Scalable Green Hydrogen

In 2024, researchers at Linköping University in Sweden introduced a solar-powered catalyst that could revolutionize green hydrogen production. The catalyst boosts efficiency by 800% compared to conventional materials, making solar-driven hydrogen significantly more viable at industrial scale.

This breakthrough represents a major leap toward clean hydrogen as a cost-effective and scalable solution. As demand rises in sectors like shipping, aviation, and heavy industry, efficient hydrogen production technologies are becoming essential.

How the Solar Catalyst Works

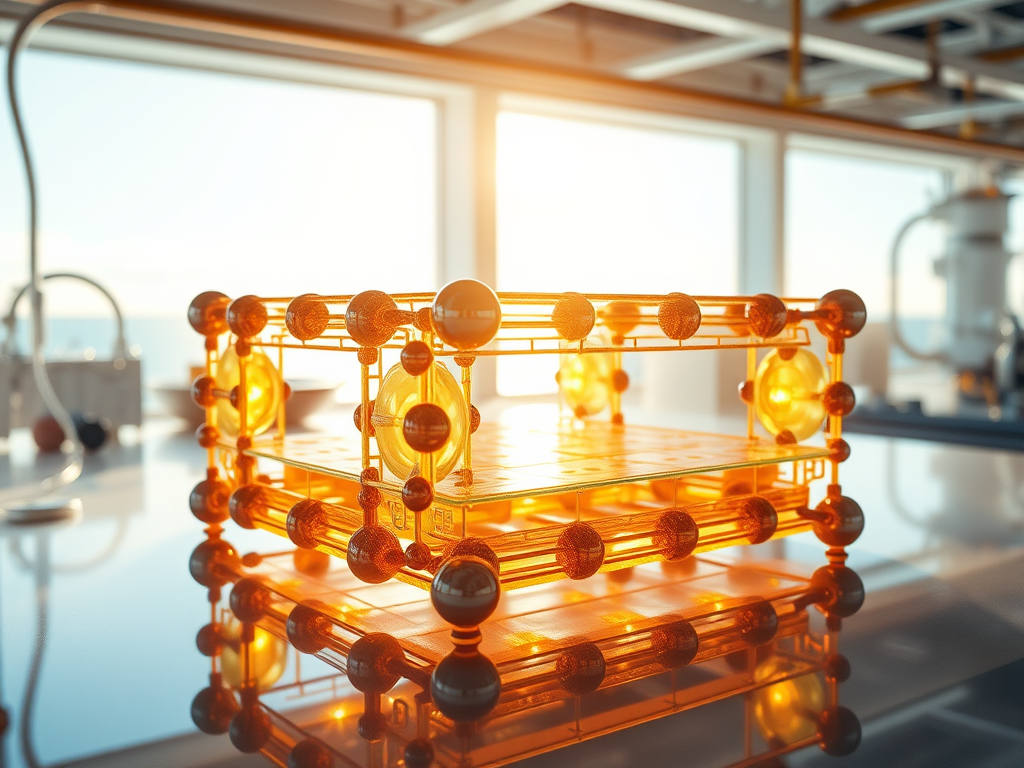

The catalyst’s success lies in its innovative multilayer structure, which includes:

- Cubic silicon carbide (3C-SiC) as the base material, selected for its excellent ability to absorb sunlight.

- A thin film of cobalt oxide, which helps separate electrical charges generated during the water-splitting process.

- A specialized surface catalyst, which enhances the efficiency of the hydrogen evolution reaction (HER).

Together, these layers facilitate more efficient water electrolysis by reducing energy loss, improving charge mobility, and minimizing recombination of charge carriers.

📈 In laboratory tests, this setup produced eight times more hydrogen under sunlight than traditional photoelectrodes.

Why It Matters for Maritime Fuel

Green hydrogen has long been considered a promising candidate for marine decarbonization. However, the high cost and low efficiency of current production methods have slowed adoption.

This new Swedish catalyst could change that by:

- Reducing production costs of green hydrogen.

- Enabling solar-powered hydrogen farms in coastal regions.

- Making hydrogen-based marine fuels (such as green ammonia and e-methanol) more economically feasible.

Example:

Shipping companies exploring dual-fuel vessels or fuel-cell powered ships could benefit directly from this technology, particularly on routes where renewable energy sources are abundant.

Global Implications and Next Steps

This development supports global climate targets and aligns with IMO decarbonization goals. As hydrogen infrastructure continues to grow, scalable technologies like this will be crucial in building a competitive green fuel market.

The next step is scaling the catalyst for industrial use, potentially through public-private partnerships or integration into solar hydrogen pilot plants in Europe or Asia.

Conclusion

This Swedish innovation marks a turning point for green hydrogen production, with real implications for the future of marine fuels. By drastically improving solar hydrogen efficiency, it lays the foundation for cleaner, renewable alternatives to conventional bunker fuels.

At GF Bunker Trade, we closely monitor such technologies as part of our mission to support clients in the transition to low-carbon and alternative marine fuels.